L’agriculture moderne est confrontée à des défis sans précédent: pénurie de main d'œuvre, volatilité climatique, et le renforcement des réglementations. Selon l'USDA, La maintenance inefficace des équipements coûte à elle seule aux États-Unis. fermes $3.6 milliards par an en temps d'arrêt et en réparations. Entre-temps, La surveillance de la santé du bétail et le respect des pesticides restent des problèmes pour les entreprises agroalimentaires du monde entier..

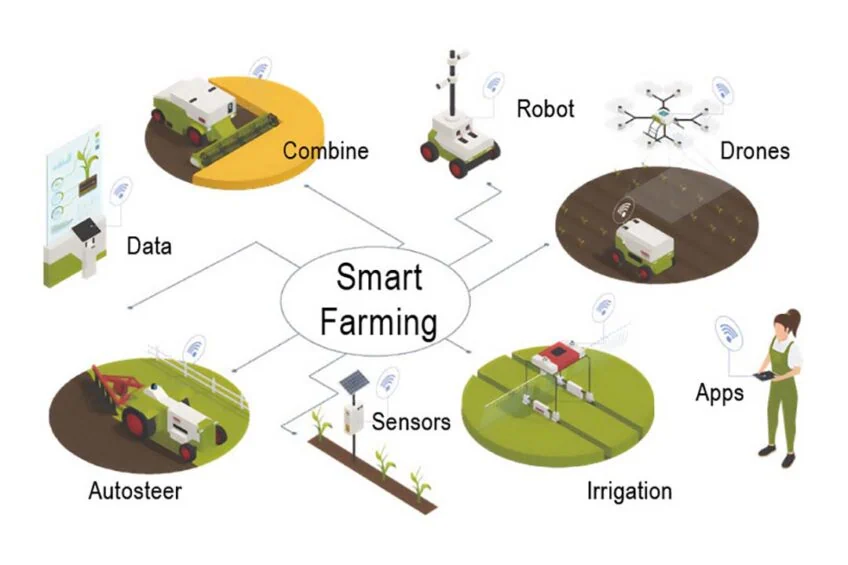

NFC (Communication en champ proche) la technologie apparaît comme un outil essentiel pour l’agriculture intelligente. Par intérim Balises NFC dans les machines, étiquettes d'oreille pour le bétail, et contenants de pesticides, les fermes réduisent leurs coûts, augmenter les rendements, et assurer la conformité réglementaire. Ce guide explore les applications pratiques, critères de durabilité, et des mesures concrètes pour adopter le NFC dans l’agriculture.

1、Applications NFC dans l'agriculture

un、Journaux d'entretien de l'équipement agricole

Problème: Le suivi manuel de la maintenance entraîne des entretiens manqués et des pannes coûteuses.

Attacher Balises NFC aux tracteurs, moissonneuses, et systèmes d'irrigation.

Capteurs (humidité/température) déclencher des journaux automatiques lors de l'analyse.

Avantages:

Réduit les temps d’arrêt des équipements de 25% (Données pilotes John Deere).

Planifie automatiquement la maintenance en fonction de l'utilisation en temps réel.

Exemple de mise en œuvre:

Une ferme de soja dans l'Iowa a réduit ses coûts de réparation de moissonneuse-batteuse de 18% en utilisant les alertes de maintenance déclenchées par NFC.

b、Surveillance de la santé du bétail

Problème: Les contrôles de santé manuels ne détectent pas les premiers signes de maladie.

Intégrez des balises NFC dans des boucles d'oreilles ou des colliers.

Scannez les étiquettes pour accéder aux dossiers de vaccination, tendances de poids, et historique de reproduction.

Avantages:

Réduit la mortalité du bétail de 12% grâce à des soins proactifs (Rapport de la FAO).

Simplifie la conformité aux règles de traçabilité de l'USDA.

Étude de cas:

Un ranch de bétail du Texas a amélioré l'efficacité des rapports sur la santé du troupeau en 40% en utilisant des étiquettes d'oreille compatibles NFC.

c、Suivi de l'utilisation des pesticides

Problème: Les journaux manuels retardent les rapports de conformité et les erreurs de risque.

Solution NFC:

Étiquetez les contenants de pesticides avec des étiquettes NFC.

Automatisez les journaux d'utilisation (date, quantité, emplacement sur le terrain) via des analyses mobiles.

Avantages:

Réduit le temps de préparation des audits de quelques jours à quelques heures.

Garantit le respect des réglementations EPA/FDA.

2、Tests de durabilité: Tags NFC dans des conditions extrêmes

Résultats des tests (-20Environnements °C à 50°C)

| Modèle de balise NFC | Résistance au gel | Résistance à la chaleur | Indice d'étanchéité |

| NTAG 223 (Standard) | Échec à -15°C | Échec à 45°C | IP65 |

| RFIDHY Aujourd'hui | A survécu à -25°C | A survécu à 60°C | IP68 |

| NFCWORK h-tag213 | A survécu à -20°C | A survécu à 55°C | IP67 |

3、Étude de cas: 15% Gain d’efficacité de récolte avec NFC

Problème: Une ferme de blé de 2 000 acres au Kansas a connu des difficultés avec des réparations d'équipement retardées et un suivi manuel des cultures..

Solution:

Toutes les moissonneuses-batteuses ont été étiquetées avec des journaux de maintenance compatibles NFC.

Implémentation du suivi des lots de récoltes basé sur NFC, du champ au silo.

Résultats (1 Saison):

- Vitesse de récolte augmentée de 15% grâce à un entretien proactif des équipements.

- Réduction de la détérioration des grains grâce à 9% via une surveillance de l'humidité en temps réel.

- Enregistré 200+ heures sur les rapports de conformité.

4、ROI du NFC dans l’agriculture

| Métrique | Méthodes traditionnelles | Solutions NFC |

| Coûts des temps d'arrêt des équipements | $18,000/année | $13,500/année (-25%) |

| Taux de mortalité du bétail | 8% | 7% (-12.5%) |

| Pénalités d'audit | $5,000/année | $0 |

| Économies annuelles | $0 | $9,500+ |

Guide de configuration pour le suivi des cultures et du bétail.

👇 Cliquez pour demander des échantillons:

Pourquoi le NFC est l'avenir de l'agriculture?

De l’automatisation des journaux de pesticides à la prolongation de la durée de vie des machines, NFC transforme les données brutes en informations exploitables. Alors que les défis climatiques s’intensifient, les systèmes d’étiquetage intelligent ne sont plus facultatifs : ils sont essentiels pour un développement durable, agriculture rentable.