Manuelle Dateneingabe in ERP -Systemen kostet Unternehmensunternehmen $5.7 millionen pro Jahr in operativen Ineffizienzen (Gartner, 2023). Für Branchen wie Fertigung und Logistik, Integration von NFC (Nahfeldkommunikation) Mit ERP -Plattformen wie SAP und Oracle schließen die Lücke zwischen physischen Vermögenswerten und digitalen Workflows.

Dieser Leitfaden bricht die technische Architektur ab, Integrationsschritte, und realer ROI des Verbindens NFC-Tags SAP- und Oracle -Systeme.

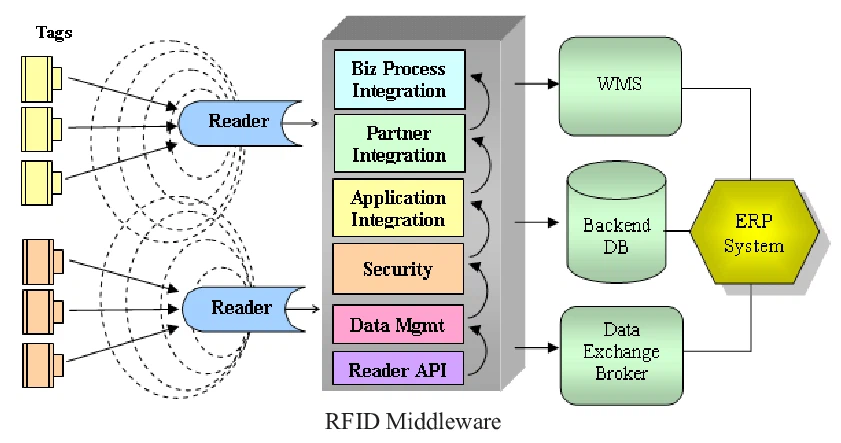

1、Technische Architektur: Wie NFC -Daten nach ERP fließen

Datenfluss:

- NFC -Leser scannt Tags auf Vermögenswerten, Werkzeuge, oder Inventar.

- Middleware (Z.B., Knotenrot, Mulesoft) verarbeitet Rohdaten.

- ERP -System (SAP/Oracle) Aktualisieren Sie Datensätze über REST -APIs.

Schlüsselkomponenten:

- NFC -Leser: Wählen Sie ISO 15693-konforme Geräte (Z.B., ACS ACR1255U).

- Middleware: Stellt die Datenformatierung sicher (JSON/XML) und Protokollübersetzung.

- ERP -APIS: SAP MM -Modul -API, Oracle IoT Cloud Connector.

2、Schritt-für-Schritt-Integrationshandbuch

Schritt 1: Wählen Sie NFC -Leser mit REST -API -Unterstützung aus

Warum ist es wichtig: Rest -APIs ermöglichen eine nahtlose Kommunikation zwischen NFC -Lesern und ERP -Systemen.

Empfohlene Hardware:

Zebra MC3330XR: Unterstützt Odata -API für die SAP -Integration.

Feig Obid Iscan: Kompatibel mit Oracle ERP Cloud.

Für die Spitze: Vermeiden Sie proprietäre Protokolle - opt für Leser mit offener Ruhe-/Seifen -APIs.

Schritt 2: Karten Sie NFC -Daten in SAP MM -Modulfelder

Konfigurationsbeispiel (SAFT):

NFC -Datenfeld SAP MM Field

Asset ID Equi-equnr

Letzte Wartung IFLM-EUFNR (Arbeitsauftrag)

Standort Equz-Standard

Werkzeuge: Verwenden Sie die Integration der SAP Cloud -Plattform (CPI) Mappings automatisieren.

Schritt 3: Automatisieren Sie Arbeitsauftragsauslöser

Anwendungsfall:

Wenn ein NFC -Scan Geräte bei erkennt 80% Lebensdauer, SAP PM-Modul generiert automatisch eine Wartungsarbeitsordnung.

Oracle Eam sendet Warnungen an Techniker per E -Mail/SMS.

3、Effizienzgewinne: 75% Weniger manuelle Einträge

Fallstudie: Automobilhersteller senken die Dateneingabekosten

Problem: 40% Die Daten der Werkstattdaten wurden manuell in SAP eingetragen, Verzögerungen und Fehler verursachen.

Lösung: NFC-Tags auf Maschinen + SAP -Integration.

Ergebnisse (6 Monate):

- Manuelle Dateneingabe reduziert durch 74%.

- Produktionsstörungen nahmen um 21%.

- Die Genauigkeit der ERP -Daten verbesserte sich auf 99.8%.

4、ROI der NFC-ERP-Integration

| Metrisch | Vor NFC | Nach NFC |

| Monatliche Handbucheinträge | 12,000 | 3,000 |

| Dateneingabemistikrate | 8% | 0.2% |

| Überprüfung der Compliance -Zeit | 40 Std. | 10 Std. |

| Jährliche Einsparungen | $0 | $1.4M |

Quelle: Gartner, Kosten für schlechte Datenqualität in der Herstellung (2023).

Letzte Gedanken

Die Integration von NFC in ERP -Systeme verwandelt statische Daten in umsetzbare Erkenntnisse. Durch Automatisierung der Vermögensverfolgung, Wartung, und Bestandsaktualisierungen, Unternehmen entsperren beispiellose Effizienz und beseitigen gleichzeitig kostspielige menschliche Fehler.