RFID tags definition: RFID (Radio Frequency Identification), commonly known as “electronic tag”, is a non-contact automatic identification technology that automatically recognizes target objects and acquires relevant data through radio frequency signals. The identification work does not require manual intervention as a wireless version of the barcode. RFID technology has the advantages of waterproof, anti-magnetic, high temperature resistance, long service life, and large reading distance, data encryption on the label, larger storage data capacity, and free storage information. The application will be for retail, Logistics and other industries have brought about revolutionary changes.

Basic composition of RFID

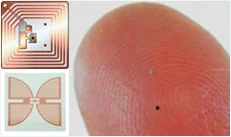

The RFID tag is physically composed of three parts: a tag, an antenna, and a reader.

Tag: consists of a coupling element and a chip. Each tag has a unique electronic code. The high-capacity electronic tag has a user write area attached to the object to identify the target object.

Reader: A device that reads (and sometimes writes) tag information and can be designed to be handheld or fixed;

Antenna: Transmits RF signals between the tag and the reader.

RFID features

Data storage: Compared with traditional forms of tags, the capacity is larger (1 bit – 1024 bit), data can be updated at any time, and can be read and written;

Read and write speed: Compared with barcode, it does not need linear alignment scanning, and the reading and writing speed is faster, which can multi-target recognition and motion recognition;

Easy to use: small size, easy to package, can be embedded in the product;

Security: The dedicated chip and serial number are unique and difficult to copy;

Durable: no mechanical failure, long life and resistance to harsh environments.

How RFID works

The basic working principle of RFID technology is not complicated: the reader transmits a specific frequency of the radio frequency signal through the transmitting antenna, and generates an induced current when the electronic tag enters the effective working area, thereby obtaining energy, and the electronic tag is activated, so that the electronic tag encodes itself. The information is sent out through the built-in RF antenna; the receiving antenna of the reader receives the modulated signal sent from the tag, and transmits it to the reader signal processing module via the antenna adjuster. After demodulation and decoding, the valid information is sent to the background host system. Correlated processing; the host system identifies the identity of the tag according to the logical operation, and performs corresponding processing and control for different settings, and finally issues a command signal to control the reader to complete the corresponding read and write operations.

RFID classification

According to the presence or absence of power, it is divided into passive and active:

Passive Tag:

The Passive sensor itself has no power supply. The power supply is from the Reader. The Reader emits a frequency to make the sensor generate energy and return the data to the Reader. The volume is relatively light and short, and has a long service life. The sensing distance is short.

Active Tag (active): The price is higher. Due to the built-in battery, the volume is larger than the Passive tag, and it has a long service life and a long sensing distance.

According to the frequency, it can be roughly divided into three categories: LF, HF and UF:

Low Frequency: 100~500 KHz The low-frequency sensing distance is short and the reading speed is slow. It is mainly 125 KHz and has good penetration ability.

High Frequency: 10~15MHz The sensing distance of the high frequency is slightly longer, and the reading speed is also faster than the frequency, which is mainly 13.56MHz;

Ultra-High Frequency/Microwave: Between 850 and 950 MHz (UHF) and 2.45 GHz, the sensing distance is the longest, the speed is the fastest, and the penetration is poor.

As a data carrier, electronic tags can play the role of identification, item tracking and information collection. Applications include:

Product anti-counterfeiting and anti-mite; Valuables management; Access control/identification; Material/product tracking; Personnel location; Transportation and distribution; Air baggage tracking; Electronic traceability, food traceability; Production line management; Railway transportation management system; Intelligent warehouse management; garment retail store export management; anti-theft management, unauthorized use management or asset management of valuable equipment; vehicle, parking lot and gas station, warehouse facility management; automatic collection of bridge fees; important, dangerous occasions Access control management; conference and timing–typical applications; animal management, personalized feeding; automatic identification of CNC machine tools; product quantity and process control in flexible processing systems; surveillance of suspects; vehicle anti-theft system and car ignition system; Intelligent library, rental product management; application of car theft and keyless door opening system; application management of car anti-theft and keyless door opening system; application of RFID in warehouse management; RFID in alcohol anti-counterfeiting and anti-mite application; RFID in parking lot Applications; RFID in pet management applications; RFID in logistics and distribution applications; RFID in warehouses Shall count; animal shall be traceable RFID; RFID applications in production line automation control