Ingebedde RFID-tags worden steeds populairder. Oplossingen voor het volgen van bedrijfsmiddelen die zijn gebaseerd op RFID-technologie combineren traditioneel de mogelijkheid om bedrijfsmiddelen te identificeren en te lokaliseren. Instead of reading the barcode or serial number of a given asset. With the advent of embedded passive RFID tags. Now opt for a “smart asset management solution” that goes beyond a single identification method.

Preserve Data

The lineage of product spec sheets, maintenance installation records. Supply chain and other data for asset equipment will always follow the tag asset itself. No matter where the asset flow transfer, it preserve well. And the always-on access system does not ensure always-on connection to the asset. Or managers have valuable information that they are reluctant to share with outside agencies.

Expectations Boosting

The accuracy of manufacturers’ expectations for production and demand is becoming more and more intense. From reducing the parts warehouse suppliers to use it to improve production efficiency. Verify the authenticity of the supply and eliminate the hid dangers of counterfeiting. The RFID embedded tag can realize the intelligent operation of asset management. Able to provide customers with economical solutions. The content of the program includes how to apply embedded and large-capacity memory RFID tags to realize asset management. Improve field service and other work aspects.

Improving Workflow

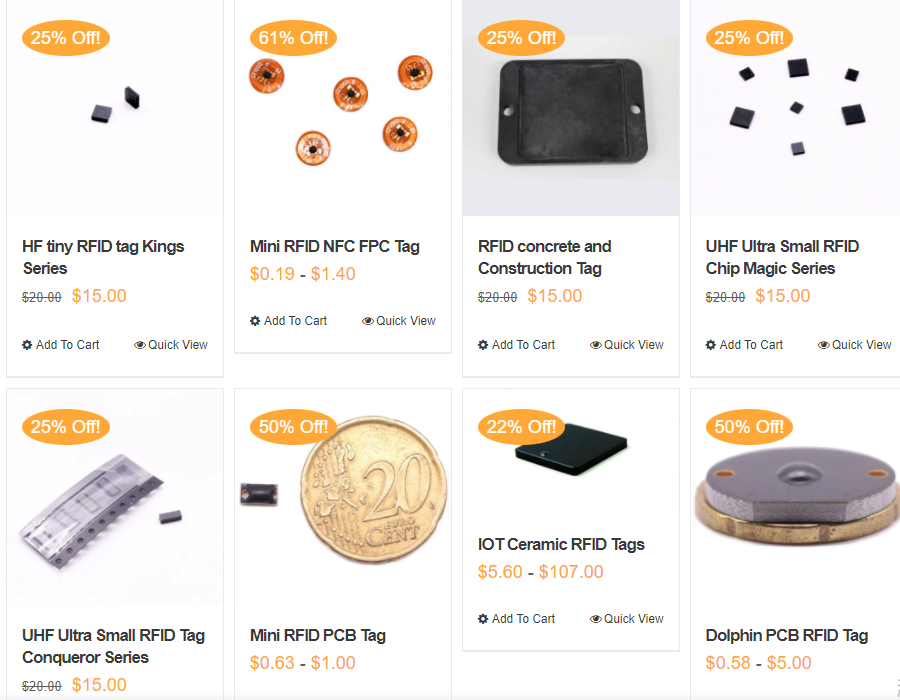

Embedding RFID tags into core critical asset equipment has many advantages for improving workflow. Bijvoorbeeld, improving asset utilization, automating the recording of maintenance operation records to replace current paper-based records and enhancing asset security. UHF tags with large memory capacity that can install or embed in metal assets. Making a large number of vertical applications also benefit from embedded RFID.

Electrical Management

Tegelijkertijd, manufacturers of computer hardware, printers. High-tech medical equipment and other industries have begun to embed RFID tags into their products. Used to identify and locate assets, or to meet other related applications. RFID-tags embed in PCB boards in the electronics industry. Allowing manufacturers to track and manage from the start of production to the final asset recycling. Manufacturers can also track and manage finished products that put into storage. Supervise the inventory cycle of assets and ensure the normal outbound transportation of assets.