RFIDHY through the standardization of automatic production line batch production, so that the RFID Glass Tags reading distance is stable, reliable performance, service life up to more than 20 years, sure impact resistance, corrosion resistance, very small; not only widely used in a large number of Industrial Automation, Industrial IOT,industrial scenes,but also in Animal tracking industry.

To make RFID Glass Tags, we need to make glass tubes first.

First of all, we need to inject heated glass liquid into the steel pipe mold to keep the heating state and soften the glass tube. The glass tube is inside the steel pipe. The temperature of the inner surface of the steel pipe can be as high as seven hundred degrees, and the temperature of the outer surface is below 300 degrees. After the glass tube is heated and softened, the softened liquid will move forward. When moving, air will be introduced into the pipe. The air needs to be compressed, so that the softened glass will stick to the inner wall of the steel pipe. Then, if the production method wants to reduce the cost and increase the production speed of glass tube, the heating temperature of the inner surface of the steel pipe can be controlled to control the thermal shock of the steel pipe, so as to maintain the best strength of the steel pipe.

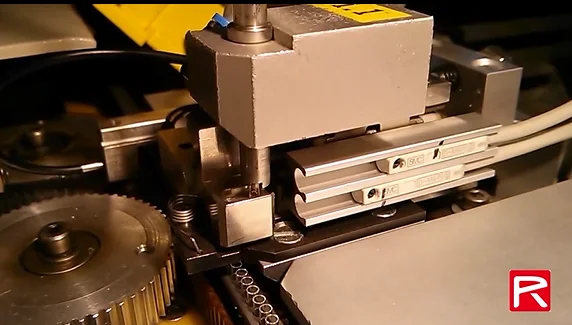

Through the machine, the production of glass tubes, one by one into a tray into a row.

Inside the glass tube, put the chip around the coil.

The epoxy material is injected into the glass tube through the needle tube machine.

The glass tube is then irradiated with ultraviolet light to make the epoxy material rapidly solidify.

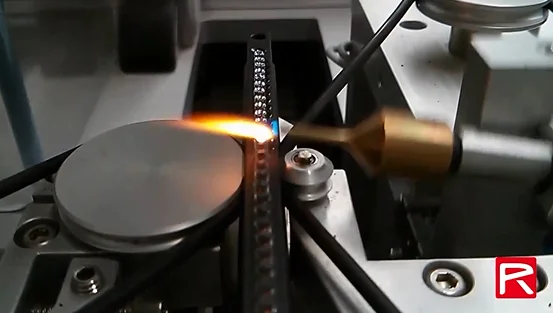

The glass bottle mouth is burned with high temperature flame to make the bottle mouth melt and fix naturally.

One by one, the tags passed the card machine test.

RFIDHY RFID Glass Tags is the best choice for your industrial production and animal management.