RFID airline luggage tag are in high demand for traditional airline tracking systems.

Small Size Label

Although there are IC shortages throughout the supply chain. But earlier this year, RFIDHY released a new RFID airline luggage tag. The tag designs to provide airlines with continuous RFID technology products. This tag is currently the smallest UHF RFID-specific product on the market. That complies with IATA (International Air Transport Association) resolutions. And is also ARCSpec U certified using Impinj’s M700 inlay.

Sustainability

RFIDHY’s RFID-etikette utilize a new type of chip that is more readily available from Impinj. The smaller size of such chips allows for more chips per wafer. Enabling greater availability when wafers are hard to come by. And this also provides a degree of sustainability for tracking applications.

Sensitivity Challenge

The Inlay’s smaller chips are easier to produce in high volumes. But their relatively high sensitivity requirements also pose challenges. As this may be too high-performance for existing airline RFID reading systems.

Threshold Problem

Spec U guidelines define minimum performance thresholds, while airline systems have a maximum threshold. The RF characteristics of the new Inlay design to solve this problem. While also meeting the requirements of existing RFID reader systems at airports. Some unnamed airlines and airports are deploying RFIDHY products with paper luggage tags. While using existing RFID reader infrastructure to read tag data as luggage passes through the airport.

Flight Resumes

Airlines have long deployed RFID technology at airports to automatically capture the tag’s unique ID number. And route information as it travels along conveyor belts to and from flights. Despite reduced air travel during the COVID-19 pandemic. RFID deployments have slowed. But the pace of deployment has begun to recover as more travelers return to airports.

Chip Shortage

The shortage of RFID chips brings challenges to traditional products. Daarom, RFIDHY built its solution using Impinj’s M730 IC. Enabling it to take advantage of the latest IC technology and inlay performance. Op dieselfde tyd, this also solves the problem of the relative shortage of IC supply. Faced by the mass adoption of RFID.

Cross-read Risk

Sensitivity cannot exceed this performance threshold due to the risk of cross-reading. Introducing more sensitive tags into an environment designed for less sensitive performance can lead to potential harm. Some existing applications require very fine-tuning.

Prevent Misreading

Airports often have a network of conveyor belts that can be physically close to each other. And if a reader on one conveyor belt reads a bag tag on the other. This creates cross-reading problems. While RFID is most commonly used for bag and route tracking, inaccurate readings. Or the wrong information captured, can affect loyalty programs and passenger-facing applications. That provide insight into the location and status of checked bags visibility.

Is jy op soek na 'n robuuste en subtiele NFC-plakker

Consequences of Mistakes

Picture this: Passengers drop off their bags on their way to a plane. and the bags travel down a conveyor belt to their plane. But a reader on the conveyor belt reads bag tag data for another flight. This resulted in incorrect messages being sent to passengers. Passengers came to the baggage claim carousel according to this wrong message but did not find their luggage. This obviously won’t be a pleasant travel experience.

Threshold Stable

Verder, route information relies on accurate tag reads, rather than capturing serial read data. Daarom, despite the high sensitivity of the new chip. it is important that the new inlay does not exceed the Spec U performance threshold. The developers of RFIDHY designed the new inlay. To provide interoperability with legacy airline baggage tracking systems and legacy RFID solutions.

Small but Beautiful

Smaller antennas help ensure that the tags meet the performance requirements for shorter read ranges. And the smaller size of the inlay and the associated weight reduction (ongeveer 20%). makes the label more sustainable. Small inlays, including chips and antennas, are more cost-effective. Because they use fewer raw materials. And using fewer materials means a smaller carbon footprint. The smaller the size, the higher the efficiency and the lower the shipping costs.

Challenge

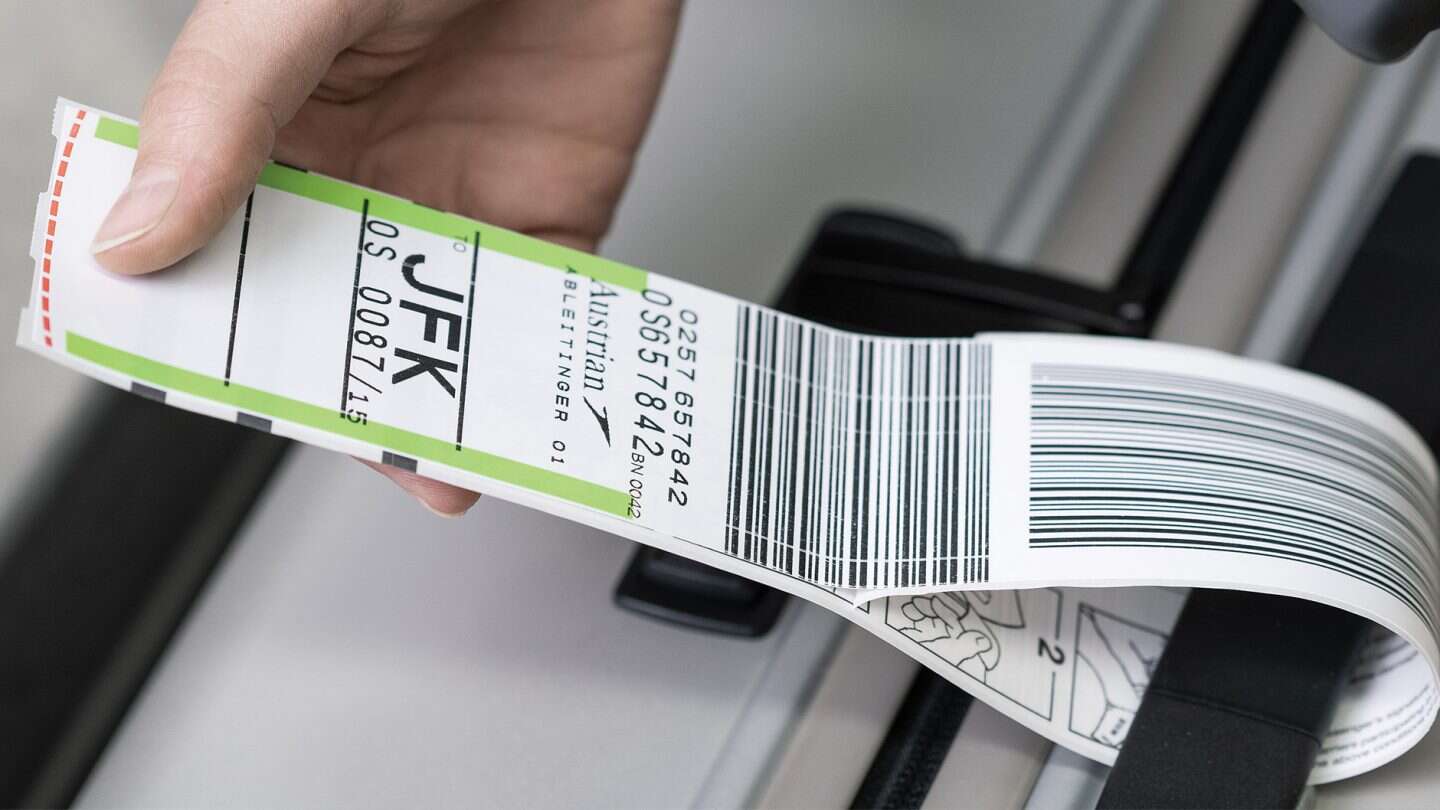

Before the introduction of inlay. The challenge for the aviation industry was that existing RFID applications could become obsolete. As tags became more sensitive. The company’s new label has been heavily used by several major airlines. With testing completed in the fourth quarter of 2021. The inlay built into the luggage tag and encodes it when the tag printed for the passenger. At a kiosk or luggage counter, the printer will encode the relevant data such as destination onto the tag. Stationary readers capture this information and send it automatically as the bag moves on the conveyor belt.

Warm Up

As the outbreak eases and travel resumes, the industry is in increasing demand for luggage tracking tags and inlays. Business travel remains limited globally, but tourism is recovering at an accelerated rate. This affects the amount of checked luggage per passenger. As leisure travelers typically carry more luggage than business travelers.

Future Plan

In the longer term, RFIDHY is developing a range of luggage tags that built into new RFID reader systems. Daarom, this new type of air luggage tag meets the needs of airlines. And ensures that there is no vacancy in the market.